The Insulation Deterioration Monitoring Module from CONPROSYS™ is a revolutionary product for measuring the insulation resistance of three-phase motors that otherwise cannot be measured without stopping the device. With the CONPROSYS™ Insulation Deterioration Monitoring Module, constant motor insulation deterioration monitoring is possible for three-phase motors, allowing for detection of possible signs of failure.

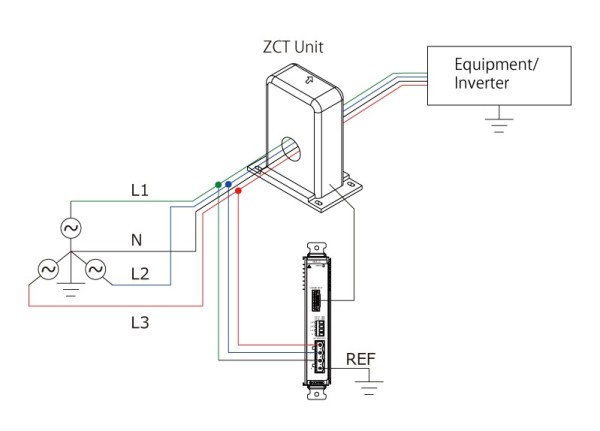

The monitoring equipment includes an Insulation Deterioration Monitoring Module (CPS-MM-LC) combined with an M2M Controller Configurable Type CPU Module. Only one CPS-MM-LC Insulation Deterioration Monitoring Module is required for each motor being measured. (Up to 16 modules*)

* The total current consumption must be 3.3 A or less for the equipment configuration.

Three-phase motors are commonly used in many moving mechanical devices such as machining equipment, water distribution pumps, and elevators. Depending on the operation time, the insulation penetration resistance of the stator coil may lead to declined performance, grounding faults, phase short circuits, layer short circuits, and other situations that may cause equipment failure, resulting in a dangerous situation. Failure of a device will not only stop the equipment but may also cause an accident that may put workers in grave danger.

Insulation deterioration event

| Grounding fault | In a grounding fault, the insulation between the electrical circuit and ground is extremely reduced, and an arc or conductor–based connection occurs. Grounding faults can lead to an increased risk of electric shock or equipment damage. |

|---|---|

| Phase short circuit | A state in which the lines between two or three of the phases are in contact with no load passing between them. Because this results in a circuit with very little resistance, a large amount of current flows through, increasing the possibility of fire or damage to the motor. |

| Layer short circuit | A layer short circuit occurs when contact occurs between the lead portions of the coil, which should be insulated. Such short circuits can result in various problems such as the number of effective coil windings to change, leading to degradations in performance. In addition, because magnetic flux also affects the short-circuited coils, the electromotive force may also be affected, leading to abnormal heating or other problems. |

The settings for the Insulation Deterioration Monitoring Module can be configured from a web browser by accessing the M2M Controller.

Basic settings including network environment settings, measurement modes exclusively used with the Insulation Deterioration Monitoring Module, power supply frequency, measurement range, and other settings can all be configured from a web browser.

For details, see the reference manual.

The monitoring screen and software are built using the CONPROSYS VTC script function and the CONPROSYS HMI screen creation function equipped with the M2M Controller.

Take advantage of a wide selection of sample script programs to begin use immediately.

Programs can also be customized as desired, including with notification emails at certain thresholds or with audible alerts.