| SYSTEM OPERATION | Continuous melt pool measurement Accurate closed-loop control of the laser power |

Configuration S/W friendly user interface Easy set up |

Process compatibility Tracks Continuous |

S/W Indicators Melt pool width Laser power Infrared image Laser status |

|---|---|---|---|---|

| MECHANICAL INTEGRATION | On-axis optical system monitoring melt pool geometry | Laser head optical path needs IR transmission ( > 1.1 um ) | Compact system – Embedded IR camera, processor and control | Integration in the laser head using an existing optical port |

| COMPONENTS | Sensor head with embedded real-time processing electronics and connectors Imaging lens Software for system configuration Infrared emitter for initial focus and optical calibration |

|

|---|---|---|

| PROCESS COMPATIBILITY | LMD process (Laser Metal Deposition) / Laser Cladding Processes | |

| OPTICAL COMPATIBILITY | Transmission of infrared radiation (above 1.1 um) from the process area to the optical port is required. * | |

| MATERIAL COMPATIBILITY | Steel powder, Stain steel powder, Stelite powder, Inconel, others. | |

| LASER POWER CONTROL | Analog signal control, 0 VDC – 10 VDC | |

| DIMENSIONS (mm) / WEIGHT | 88 mm x 60 mm x 92 mm / 0.5 kg | |

| POWER SUPPLY | 24 VDC, 6W | |

| IMAGING LENS | According clients specifications and needs. Several optical configurations available. | |

| MECHANICAL ENCLOSURE | IP67 rated mechanical enclosure with embedded heatsink Embedded waterblock for air / water cooling |

|

| MECHANICAL INTERFACE | C-mount thread with counterthread for tight adjustment | |

| INFRARED CAMERA | VPD PbSe camera, 64×64 pixels (pixel size: 50 microns) MWIR response (1 -5 um), frame rate 1000 images per second |

|

| COMMUNICATION INTERFACE | Gigabit Ethernet (RJ-45) | |

| MINIMUM REQUIREMENTS | PC with processor i5, RAM memory: 8 GB Hard disk available: 1 GB, O.S.: Windows 10 or later (32/64 bits) |

|

| PROCESS CONTROL | Selectable modes: Automatic, Manual | |

| PROCESS CONFIGURATION | Selectable process configuration: Tracks, Continuous Initial laser power Track length (Tracks mode) |

|

| OTHER FEATURES | 2x digital input, 2x digital output (multiple functionalities) Process data logging |

Constant laser power causes overheating and lack of adherence to the base

material.

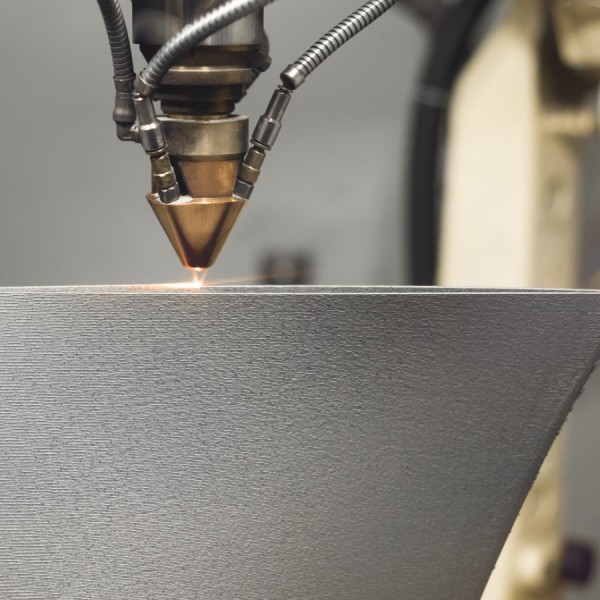

Laser power is closed loop controlled in real time using the information

extracted from the melt pool IR images.

Avoids overheating of the part under process and allows a continuous and high quality

manufacturing process.

Reduces rates of defective parts, material reduction cost up to 60% and saves 50% more

energy than uncontrolled processes.

To the base material due to excess of laser power application (average reduction of

dilution: > 40%)

Increasing productivity.