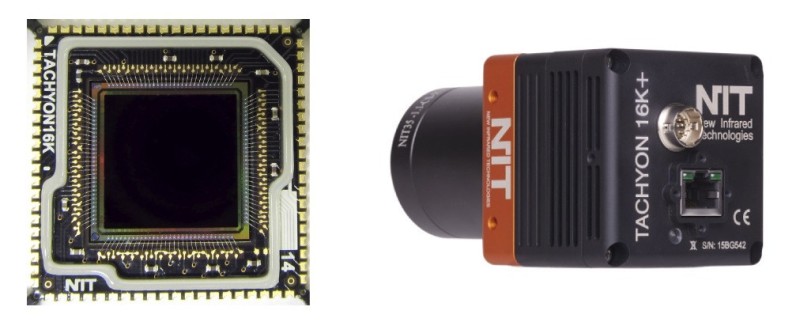

Monitor and control systems based on high speed MWIR cameras are being adopted by many companies and clients around the World to improve their services and products

Machine manufacturers introduce new performances in their machine using NIT’s products adding stronger value to their final product. System Integrators, on the other hand, source components from multiple manufacturers including NIT’s products and combining them on the customer’s production floor.

NIT has strong collaboration with Universities and Research Centers. These institutions always are in the forefront of technology and with NIT’s products are discovering new solutions applicable to the market.

Customers which has their business perfectly running but are looking constantly for continuous improvement in quality and process production.

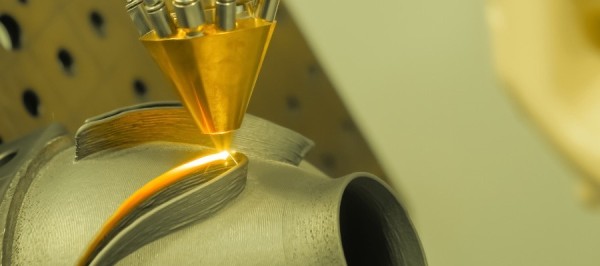

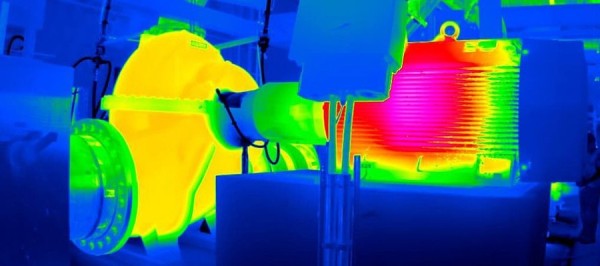

Process monitoring to identify in real time the formation of defects. In general, the goal is to determine the presence of porosity, contaminant inclusions, swelling, warping and other defects. Temperature evolution in the material could also be measured.

Based on real-time processing of the images performed internally by the camera, the system continuously extracts key parameters of the melt pool such as temperature gradients, geometry, area, and width. Using advanced algorithms for analysis and control, CLAMIR controls, in real time, the power of the incident laser with the objective of keeping the deposition process within the range of tolerances defined by the user

These processes use laser radiation to apply a specific thermal treatment for hardening the surface of the metal while retaining the flexibility of the metal underneath. Accurate monitor of heat distribution and dynamics ensure the surface is heated to the correct level to achieve the desired strength, while leaving the internal properties of the metal unaffected.

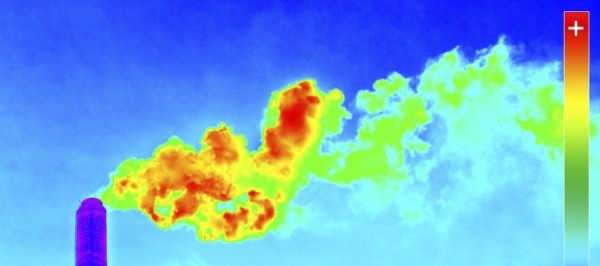

MWIR detectors are key elements of IR spectrometers. Volcanic sulfur dioxide concentration measurements, pollutants in the air, greenhouse gases concentrations etc, are some of the multiple applications demands better and more advanced MWIR detectors.

Hot end real time information for optimizing production process automatically mixing artificial intelligence and algorithms.

Methane, propane, ethanol, and sulfur hexafluoride and other gases invisible to the naked eye. When used on board drones, MWIR detectors can monitor facilities that contain gases (pollutants, toxic gases) for maintenance purposes.

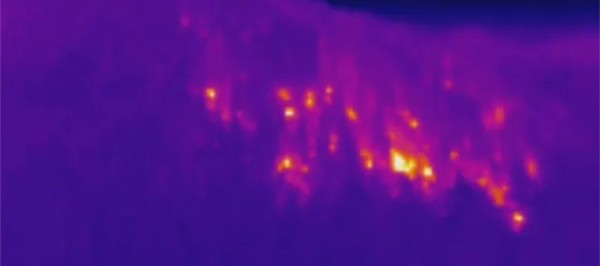

Fire safety: Fire detection, forest-fire analysis.

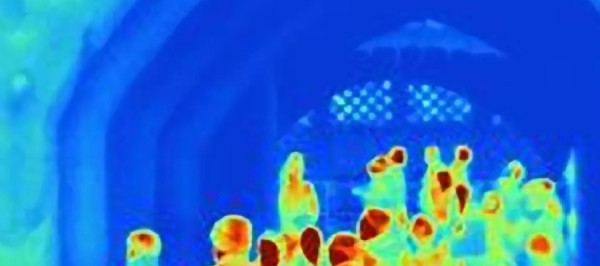

Thermal camera makes easy to safely guard structures, people, and property. IR technology allows to have an affordable solution with high returns.

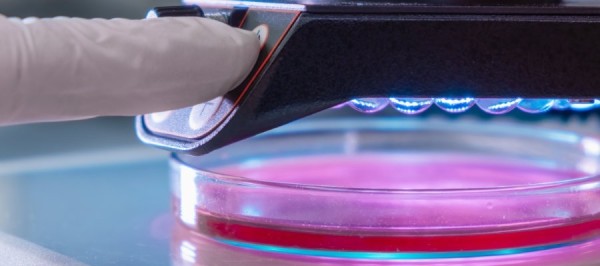

Improvement of the screening performance to facilitate monitoring procedures with the use of best-in-class thermal imaging cameras and systems of NIT

Improvement of the screening performance to facilitate monitoring procedures with the use of best-in-class thermal imaging cameras and systems of NIT

And many others, contact us for your personal case/issue